Sustainability and the human impression on planet Earth have generated discussions for a very long time. Points are tackled from completely different instructions, generally economically and generally environmental and social. Inexperienced (2012) addresses the “triple backside line”, which embody social, financial and environmental features, passing by the environment friendly use of supplies, materials life cycle evaluation and appropriate supplies for vitality effectivity.

“Inexperienced manufacturing” processes are chargeable for revolutionizing conventional manufacturing processes, bringing sustainable and accountable options. Amongst all of the aims of sustainable manufacturing, the principle one is expounded to rising useful resource effectivity and lowering waste. This shift to greener manufacturing processes not solely advantages the surroundings, however can even enhance an organization’s backside line and long-term competitiveness in an more and more environmentally acutely aware market (Singh et al., 2021).

Haas and Sander (2020) analyze of their research the function of emissions efficiency requirements within the broader context of the European Inexperienced Deal. By highlighting the significance of efficient environmental insurance policies and regulatory measures, the authors supply essential insights into how the EU can tackle the challenges of decarbonizing the transport sector, essential to reaching sustainability objectives and combating local weather change. These approaches function a reference and inspiration for the Brazilian state of affairs, particularly contemplating the same challenges confronted by Brazil in relation to the decarbonization of transport and assembly sustainability objectives. By analyzing European emissions efficiency insurance policies and their relationship with the Inexperienced Deal, Brazil can discover helpful classes to develop its personal insurance policies and extra sustainable transport initiatives, aligned with its worldwide environmental and local weather commitments.

With regards to present analysis, many are carried out with the identical remaining goal, that’s, lowering vitality consumption and lowering carbon emissions. A transparent instance is within the research carried out by Athanasopoulou et al. (2018), whose focus is on evaluating carbon emissions between combustion automobiles and electrical automobiles. Moreover, the authors Panagiotopoulou et al. (2022) and Hailu et al. (2018) tackle, of their analysis, vitality losses throughout the usage of automobiles, in addition to excessive emissions ensuing from the usage of non-renewable vitality within the manufacturing processes of automobiles. One other essential subject for CO2 discount research is the discount of auto weight, as prompt by Wenlong et al. (2016), which is addressed all through this analysis.

On this context, the development of environmental and authorities legal guidelines has been urgent automotive producers to constantly enhance the protection and gasoline financial system of low-cost vehicles and scale back the emission of greenhouse gases. Along with the desire for the usage of non-fossil fuels and for different types of automotive traction (similar to electrical), efforts are wanted to enhance the vitality effectivity of automobiles by the automotive trade, similar to lowering automobile weight, optimization of the combustion course of, discount of the volumetric displacement of engines, hybridization, amongst different technological advances (CETESB, 2017). In line with Van den Brink et al. (2001) for each 100 kg of additional mass (based mostly on 1000 kg of auto mass) there may be presumably a 7–8% improve in gasoline consumption, as measured by the European gasoline take a look at cycle.

These necessities consequently have an effect on the collection of design and supplies and the reaching these objectives requires a mixture of high-tech supplies, revolutionary design, superior manufacturing processes and a detailed relationship between design, manufacturing and supplies engineers (KRUPITZER and HEIMBUCH, 2005). Institutes and analysis facilities all over the world have put lots of effort into the event of latest merchandise that result in these objectives. Presently, a number of life cycle instruments are used to guage new automobile constructions for sustainability and design with environmental views in relation to greenhouse fuel emissions, similar to Life Cycle Evaluation (LCA), Life Cycle Price (LCC) and Life Cycle Optimization (LCO) (MAYYAS et al., 2012).

The estimate of environmental impacts over the helpful lifetime of automobiles, from cradle to grave, might be obtained by the Life Cycle Evaluation (LCA). In line with some authors (SULLIVAN et al., 2010; DAS, 2000; SONG et al., 2009) the life cycle of automobiles and most different merchandise consists of 5 phases: 1) extraction of uncooked supplies and manufacturing of fabric, 2) manufacture and meeting of the product, 3) use of the product, 4) upkeep and restore, and 5) finish of life (Fig. 1). For automobiles, the greenhouse fuel emission charges within the materials manufacturing and automobile operation phases are the biggest and finest understood, however further work must be carried out for some superior supplies beginning for use on a bigger scale within the automobiles.

Manufacturing a automotive entails a number of steps, from the preliminary design to the ultimate meeting of the automobile. One of many modules that make up the automobiles, whose course of is roofed on this article, is known as “Physique in white” (BIW) and this types the principle construction of the automobile, composed of steel panels or supplies which are molded, reduce, welded and joined collectively exactly to create the spine of the automotive. Thought-about the stage earlier than portray and putting in the engine, earlier than the chassis subassemblies or trims (glass, locks, door handles, seats, upholstery, electronics, and so forth.) are built-in into the construction (Fig. 2).

It’s estimated that lowering the load of the automotive’s BIW supplies a discount in emissions on the finish of its life cycle. In latest many years, a number of high-technology steels have been developed (Fig. 3), with the goal of accelerating the yield restrict and resistance restrict of steels, enabling the discount of thickness and greenhouse fuel emissions, with assured sustaining the mechanical properties of BIW. Changing supplies generally utilized in metallurgy with new technology steels is a vital think about reaching reductions in greenhouse fuel emissions. The so-called superior excessive power steels (AHSS – Superior Excessive Power Metal) have appeared available on the market during the last 20 years, with the Usibor 1500 and Ductibor 500 steels produced by Arcelor Mittal and such steels proceed to advance technologically similar to Usibor 2000, Ductibor 1000, together with Martensitic Metal – Scorching Rolled, Hardening Metal Coated, Twin Section Excessive Ductility and Complicated-Section.

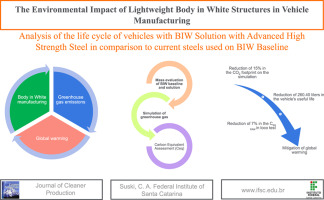

On this paper, the central theme is expounded to the evaluation of the life cycle of automobiles with Physique in White developed in new technology steels (BIW Answer), additionally referred to as superior excessive power steels (AHSS – Superior Excessive Power Metal), compared to present steels used (BIW Baseline), as a way to scale back the thickness of the metal plates and, consequently, the mass of the automobile and the emissions of greenhouse gases, with the assure of mechanical properties equal to or superior to these already used.