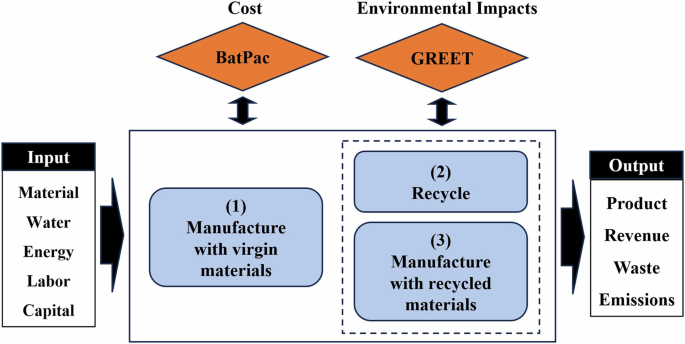

This part presents the outcomes of the fundamental enterprise situation relating to environmental and financial efficiency. Then, the sensitivity evaluation follows. We report the evaluation outcomes from two points: (1) recycling (open-loop mannequin) and (2) cell remanufacturing (closed-loop mannequin). The scope of recycling is from the gathering of spent LIBs to the recycling of collected batteries. Then, the recycled supplies had been assumed to be bought available in the market, making the fabric circulation in an open loop. Furthermore, cell remanufacturing consists of assortment and transport, recycling, cathode remanufacturing with the recycled supplies, and cell remanufacturing with the remanufactured cathode, forming the fabric circulation closed loop.

The first objective of selling EVs is to decarbonize the transportation sector, i.e., decreasing vitality consumption and GHG emissions. Determine 3 illustrates the full vitality consumption and GHG emissions in recycling and cell (re)manufacturing. The recycling by pyrometallurgy course of consumes roughly 4.59 MJ/kg cell of vitality and emits 1224.12 g/kg cell of GHGs and that by hydrometallurgy course of makes use of 23.73 MJ/kg cell of vitality and releases 1730.79 g/kg cell of GHGs.

A cell manufactured utilizing virgin supplies consumes 297.51 MJ/kg cell of vitality related to 20,847.50 g/kg cell of GHG emissions. A cell remanufacturing with recycled supplies consumes roughly 256.51 MJ/kg cell of vitality and emits 20,167.43 g/kg cell of GHGs for pyrometallurgy and 266.14 MJ/kg cell of vitality and emits 18606.58 g/kg cell of GHGs for hydrometallurgy. The outcomes present a possible to cut back vitality consumption and GHG emissions by roughly 10.7% when batteries are produced by hydrometallurgy utilizing recycled contents as a substitute of virgin supplies.

The decrease environmental impacts of cell remanufacturing with recycled supplies are primarily as a result of LIB recycling avoids half or all the virgin materials extraction and refining actions required in cell manufacturing with virgin supplies. Recycling is regularly known as city mining and is part of the answer to decrease the environmental impacts of LIB manufacturing (Beaudet et al., 2020).

Whereas the recycling outputs in EverBatt give outcomes solely from the recycling course of, excluding assortment and transport, this examine studies the recycling outputs, together with assortment and transport, and recycling itself, for a extra express evaluation. Nonetheless, for the fundamental enterprise situation thought-about, the outputs from assortment and transport are comparatively insignificant. Thus, the vitality use is 0.16 MJ/kg feedstock, and the GHG emission is 12.34 g/kg feedstock. It’s because the thought-about geographical construction requires a brief common distance from assortment websites to the recycling plant, i.e., 95.7 km (60 miles).

The financial evaluations for recycling with hydrometallurgical and pyrometallurgical processes are illustrated in Fig. 4. The hydrometallurgical course of ($3.50/kg feedstock) is less expensive than the pyrometallurgical course of ($3.63/kg feedstock). As well as, the revenues from these processes are $4.05/kg feedstock and $3.06/kg feedstock, respectively. In response to EverBatt, the income is estimated by assuming that recovered Cu and Al shall be bought to the market. From these prices and income constructions, the revenue of the hydrometallurgical course of is $0.55/kg feedstock, whereas that of the pyrometallurgical course of is $−0.57/kg feedstock. Therefore, for the open-loop enterprise mannequin (from the gathering of spent LIBs to the recycling course of), the pyrometallurgical course of might not be economically possible below the present market state of affairs.

It’s obligatory to notice that Everbatt 2023 offers an identical chart as Fig. 2 within the Output sheet, and its newest model has a minor bug in presenting the feedstock cost. We fastened the bug for our evaluation and offered a bug report in Appendix B.

The numerous components affecting financial efficiency are materials and capital prices. The pyrometallurgical course of consumes much less supplies than the hydrometallurgical course of. Nonetheless, the capital value, different fastened prices, and upkeep value of the pyrometallurgical course of are increased than for the hydrometallurgical course of, making it much less cost-effective.

For the closed-loop enterprise mannequin (from assortment of spent LIBs to cell remanufacturing), Desk 1 summarizes the prices of three doable cell (re)manufacturing processes utilizing virgin supplies and recycled supplies from the pyrometallurgical and hydrometallurgical processes. The full prices of cell remanufacturing with recycled supplies by hydrometallurgical and pyrometallurgical processes are $24.64/kg cell and $29.10/kg cell, respectively, whereas that of producing utilizing virgin supplies is $27.74/kg cell. Due to this fact, pyrometallurgy might not be appropriate for recycling as a result of it’s much less cost-effective even than manufacturing with virgin supplies below the present market state of affairs. Nonetheless, hydrometallurgy-based cell remanufacturing exhibits increased financial advantages than manufacturing with virgin supplies, saving roughly 11.3% of the prices. The price of supplies primarily accounts for this value saving.

In response to the outcomes, solely hydrometallurgy-based cell remanufacturing could also be economically and environmentally pleasant in comparison with cell manufacturing utilizing virgin supplies.

The LIB recycling business continues to be in its creating section. Due to this fact, it could encounter a number of uncertainties relating to technological, industrial, and market environments. Therefore, a sensitivity evaluation particular to the UAE market was performed to look at the affect of 4 various factors on the financial and environmental performances of LIB recycling: provide quantity of spent LIBs, buy value of spent LIBs, market value of recovered metals, and LIB chemistry.

We constructed a number of check instances to look at these components, as offered in Desk 2. Case C1 with the spent LIB provide quantity of ‘M’ represents the fundamental enterprise situation mentioned in Part 5.2. In instances C2 and C3, the spent LIB buy prices had been modified from the fundamental case to 0.97 ( + 20%) and 0.64 ( − 20%), respectively. Circumstances from C4 to C7 study the market value adjustments of Co and Ni of +20% and −20%, respectively, as a result of they’re the most important recovered supplies and have increased financial values than different supplies. For every case, the provision quantity of spent LIBs was modified to +20% (H) and −20% (L) from the fundamental provide quantity (M). Part “Battery chemistry” offers evaluations of various battery chemistries in comparison with the fundamental case, Case C1–M.

This subsection analyzes the impression of the change within the spent LIB buy prices on the financial performances. Desk 3 offers the outcomes of instances with adjustments within the spent LIB buy value. As the acquisition value will increase in case C2, the recycling and cell manufacturing prices additionally enhance, and vice versa in case C3. Notably, the pyrometallurgical recycling just isn’t worthwhile for increased and decrease buy prices than different processes. The cell remanufacturing with recycled supplies by pyrometallurgy is extra expensive than that with virgin supplies. Columns Δ12 and Δ13 present the relative change within the metrics from instances C1 to C2 and C3, respectively. Hydrometallurgy is extra delicate to the change within the spent LIB buy prices than pyrometallurgy. As a result of vitality use and GHG emissions don’t change relating to the spent LIB buy prices, the environmental outcomes are the identical as the fundamental case.

As a result of the prices of uncooked supplies are essentially the most important parts within the whole value of your complete remanufacturing course of, we evaluated the impression of the market costs of worthwhile metals, together with Co and Ni, on the financial efficiency of the recycling and manufacturing processes. The market costs of Co and Ni within the fundamental situation are $28.70/kg and $16.00/kg, respectively. From this baseline, in Desk 4, case C4 (C5) considers a + 20% ( − 20%) of the Co value, and case C6 (C7) considers +20% (-20%) of the Ni value.

The market value adjustments of Co and Ni monotonically have an effect on the financial efficiency of the recycling course of. Because the steel costs enhance, the prices and revenues of the recycling course of enhance and vice versa. The pyrometallurgical course of just isn’t worthwhile in all instances for the open-loop enterprise mannequin, leading to it being extra expensive in all instances for cell (re)manufacturing in contrast with different processes. The hydrometallurgy-based cell manufacturing outperforms manufacturing with virgin supplies in all instances. Importantly, the market value adjustments of Co and Ni didn’t have an effect on vitality use or GHG emissions.

The manufacturing quantity of recycling crops is instantly proportional to the provision quantities of spent LIBs. Nonetheless, the quantity of spent LIBs might differ in line with societal actions, enterprise environments, and authorities insurance policies. Thus, we examined +20% and −20% adjustments within the provide quantities of spent LIBs in all instances to research the sensitivity of the financial performances to the provision quantities of spent LIBs. Determine 5 illustrates the outcomes of recycling prices, recycling revenue, and cell remanufacturing value relating to the provision quantities of spent LIBs: +20% (H), fundamental (M), and −20% (L).

As proven in Fig. 5(a), in all instances for each recycling applied sciences, as the provision quantity of spent LIBs decreases, the recycling value ($/kg feedstock) will increase. That is primarily as a result of economies of scale within the recycling crops. Furthermore, the pyrometallurgical course of has a better constructive slope of the recycling value than the hydrometallurgical course of. This can be associated to the expensive services of the pyrometallurgical course of, even for a small plant.

Determine 5(b) exhibits the income of the recycling processes in all check instances for various LIB provide quantities spent. The identical sample seems in all instances, such that bigger crops generate extra revenue per kg of feedstock. Furthermore, the pyrometallurgical course of is economically infeasible whatever the completely different spent LIB provide quantities.

The manufacturing quantity of the cell remanufacturing additionally relies on the provision quantity of spent LIBs. Thus, we analyzed the impression of the provision quantity of spent LIBs on the cell remanufacturing prices, as offered in Fig. 3(c). As the provision quantity of spent LIBs decreases (H → M → L), the cell remanufacturing value will increase in all instances. Furthermore, the cell remanufacturing value from H to M exhibits a steeper enhance in comparison with that from M to L. Thus, the cell remanufacturing value could also be extra delicate at a excessive manufacturing quantity.

For the price of cell manufacturing utilizing virgin supplies, EverBatt confirmed minimal variations with respect to the cell manufacturing quantity. From our evaluation, such variation could also be associated to numerical errors attributable to rounding decimal values and several other multiplications of decimal values. Thus, we take into account that the cell manufacturing prices with virgin supplies are in step with diverse manufacturing volumes.

Just like the adjustments in spent LIB buy value and steel market value, completely different portions of spent LIBs didn’t have an effect on vitality use or GHG emissions. This means that monetary and manufacturing volumetric components might not have an effect on the environmental outcomes per unit product.

The essential enterprise situation solely thought-about the recycling of NMC111 (LiNi1/3Mn1/3Co1/3O2) cells. Thus, the final issue within the sensitivity evaluation is battery chemistry to find out the environmental and financial impacts of recycling different NMC cells, together with NMC532 (LiNi0.5Mn0.3Co0.2O2), NMC622 (LiNi0.6Mn0.2Co0.2O2), and NMC811 (LiNi0.8Mn0.1Co0.1O2) (Rinkel et al., 2022). Desk 5 exhibits the outcomes of this evaluation, wherein all different components are the identical as in case C1 aside from the battery chemistry.

When it comes to recycling value, NMC111 is the most expensive, whereas NMC532 is the least expensive, whatever the course of applied sciences. For recycling revenue, NMC111, with the hydrometallurgical course of, is essentially the most aggressive at $0.55/feedstock in comparison with different battery chemistries. As well as, the pyrometallurgical recycling course of was decided to be economically infeasible for all battery chemistries thought-about. All battery varieties with the pyrometallurgical course of present comparable outcomes for vitality use, whereas NMC811 consumes the bottom vitality with the hydrometallurgical course of. For GHG emissions with the pyrometallurgical course of, NMC111 is extra environmentally pleasant than others, and with the hydrometallurgical course of, NMC811 is extra environmentally pleasant.

Within the open-loop enterprise mannequin, NMC111, with the hydrometallurgical course of, exhibits the most effective financial efficiency however the worst environmental impression. Nonetheless, NMC811, with the hydrometallurgical course of, exhibits the most effective environmental profit however the lowest financial efficiency.

The decrease a part of Desk 5 offers the evaluation outcomes of the closed-loop mannequin for various battery varieties. Owing to the completely different chemical compositions, every battery kind ends in barely completely different manufacturing volumes of cathode supplies from the identical quantity of spent LIBs, 43,750 tons/12 months. NMC532 yields the bottom cell manufacturing value in comparison with others. Total, within the closed-loop enterprise mannequin, NMC532 is the most effective by way of financial points, and NMC111 is appropriate by way of environmental efficiency. Nonetheless, NMC811 exhibits the worst financial and environmental outcomes and different battery varieties present comparable outcomes.

Whereas NMC batteries have been the first focus of this examine as a result of their predominant utilization within the UAE, the rising significance of LFP batteries in world markets, significantly in China, necessitates additional investigation. LFP batteries have gotten more and more outstanding; nevertheless, their recycling poses distinct challenges. Not like NMC and different cathode chemistries, LFP batteries have a decrease financial worth as a result of their diminished high-value steel content material, making standard hydrometallurgical or pyrometallurgical recycling strategies much less viable. As an alternative, direct recycling has been recognized as a extra appropriate method for LFP batteries (Roy et al. (2024)).

Xu et al. (2020) evaluated the financial and environmental impacts of direct recycling for LFP batteries utilizing EverBatt 2019. Their evaluation, based mostly on the recycling of 10,000 tons of spent LFP batteries within the U.S., reported vitality consumption of three.5 MJ per kilogram of cell recycled, greenhouse fuel (GHG) emissions of 650 grams per kilogram of cell recycled, and a cost-to-revenue ratio indicating potential profitability at $2.1 per kilogram for recycling prices and $3.2 per kilogram for income. Nonetheless, these estimates had been derived utilizing EverBatt 2019, which lacked detailed modeling of the most recent recycling course of and didn’t incorporate the most recent course of information or financial inputs.

In distinction, this examine utilized EverBatt 2023, which integrates important updates, together with detailed modeling of preprocessing levels to supply black mass, together with revised background information from BatPaC 5.0 (2022), GREET 2022, and the latest materials and labor value information. Beneath the fundamental situation C1, recycling 43,750 tons of spent LFP batteries required 30.0 MJ of vitality per kilogram of cell recycled and resulted in 2,427 grams of GHG emissions per kilogram. The up to date financial evaluation revealed a diminished value of $0.34 per kilogram of cell recycled and an elevated income of $4.62 per kilogram, indicating a notable enchancment in profitability in comparison with earlier estimates.

The up to date course of modeling and assumptions integrated in EverBatt 2023 underscore the numerous impression of the vital supplies restoration module, which was not explicitly included in EverBatt 2019. This evaluation demonstrates that whereas recycling LFP batteries stays a viable choice, it entails increased vitality consumption and GHG emissions in comparison with earlier research. These findings emphasize the significance of using up to date instruments and methodologies to guage the environmental and financial implications of battery recycling processes comprehensively.

This evaluation offers a preliminary exploration of LFP battery recycling, motivated by their rising world significance. Whereas the findings supply worthwhile insights, they depend on preliminary assumptions and modeling that require additional validation. The upper vitality consumption and GHG emissions noticed on this examine spotlight the necessity for cautious scrutiny of things equivalent to regional recycling infrastructure and feedstock traits. Future analysis ought to give attention to detailed sensitivity analyses and real-world validation to refine these outcomes and assist the event of tailor-made recycling methods for LFP batteries.