It’s been 2 years since we final spoke to Dennis Savic and the crew at Australia’s first electrical bike producer, Savic Bikes. The nice information is that Savic has managed to navigate the chaos of the worldwide pandemic and has been working tirelessly to carry its first manufacturing bike to market.

After listening to the information that Savic had secured a cope with Bosch Australia to supply ABS for the C-Sequence electrical cafe racer. And that they’d accomplished their first spherical of main street exams, we thought it was time to the touch base with Dennis and his crew once more to see what that they had in retailer for us in 2023.

What’s been occurring at Savic Bikes since we final spoke?

There was rather a lot that has occurred because you final coated the 2019 prototype launch.

In 2020 we obtained Enterprise Capital funding and the crew designed and constructed our first manufacturing consultant prototype. We additionally leased our premises in West Melbourne and made a begin on our meeting facility. Regardless of the challenges introduced by COVID, in 2021 the crew efficiently sourced and examined all main prototype parts and we completed off the yr with a profitable capital elevate together with a authorities grant, authorities mortgage, and a profitable first street take a look at.

In 2022 it’s been full steam forward as now we have constructed our subsequent 2 prototypes. One has been by vigorous on-road testing (in addition to attending business and buyer occasions across the nation) whereas the opposite has been by ABS Growth with Bosch Australia and ADR Authorities Compliance, which is our ultimate milestone earlier than we’re in a position to begin pilot manufacturing and first buyer deliveries.

Have there been any adjustments within the design and engineering of the Savic C-Sequence?

Sure, there have been important adjustments over the previous couple of years.

We’ve fully re-designed the battery pack structure. In 2019 our speculation was that pouch cells could be finest, however we couldn’t get the design, the provider, or the associated fee goal proper. It additionally introduced longer-term sturdiness considerations. So we moved to a prismatic cell structure and altered suppliers and while we had some challenges in the beginning, all these points have been resolved now and we’re assured that now we have a fantastic high quality battery in our bikes.

Just like the battery pack, it took us a while to search out the best motor provider and value construction, there have been positively just a few challenges and classes learnt alongside the best way however we’ve discovered one who has been incredible to cope with and delivered some nice high quality motors. So, whereas it was a troublesome street, we obtained there ultimately. Persistence pays!

The 2019 and 2020 prototypes each had welded metal frames. In bigger industries, this makes numerous sense because it’s one of many lowest-cost supplies that has good efficiency traits. The problem with metal frames is that they require many, many welding jigs and fixtures so it’s very costly, particularly for an early-stage start-up.

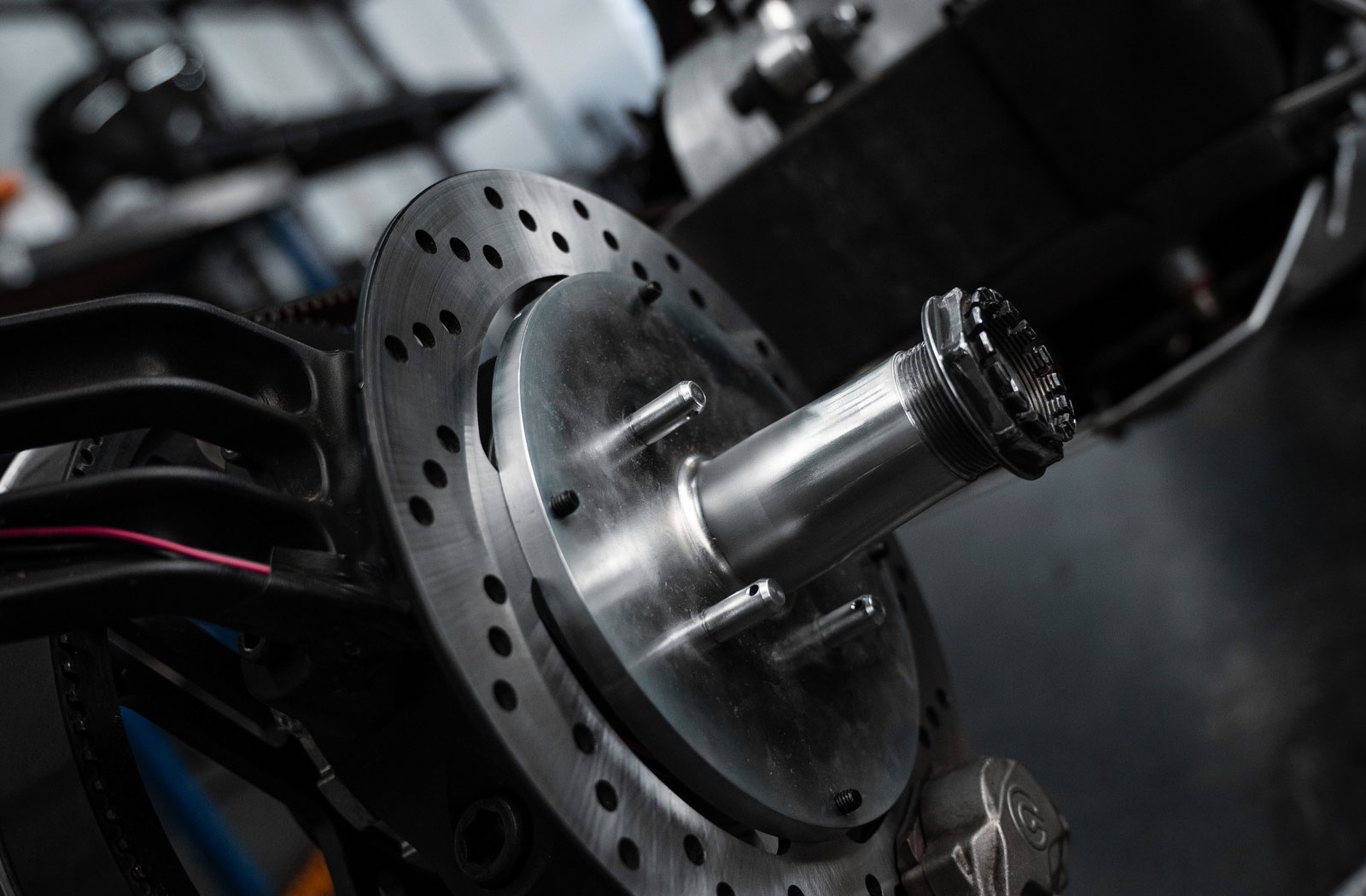

The opposite main drawback with this, which we discovered, is should you attempt to do it cheaper with fewer fixtures/jigs, you’ll not get the tolerance you want for the rear hub. We learnt rather a lot over the method and re-designed EVERYTHING in order that we may forged it out of aluminium. While you forged one thing, it doesn’t come out of a mould and go onto a motorcycle, there’s a machining course of earlier than it goes off for coating. Whether or not that be portray, powder coating, or anodizing. However that machining course of is what drills/faucets all of the holes within the merchandise in order that it’s going to be very exact. The entire course of can also be environment friendly sufficient that it fits our enterprise’ value targets. To not point out the profit and recyclability of aluminium so it matches with our firm values as effectively.

How do the C-Sequence fashions differ?

The C-Sequence (standing for Cafe Racer Sequence) is available in two variants, the top-spec Alpha and the city Delta. Each look precisely the identical, the primary distinction is the battery measurement, leading to totally different energy outputs and costs.

| ALPHA PRICE $26,990 AUD journey away POWER – 60KW TORQUE – 200NM HORSEPOWER – 80HP CHARGE – 4.5 HOURS 0-100 km/h – 3.5s RANGE: – 200+ KM *mixed | DELTA PRICE – $19,990 AUD journey away POWER – 40KW TORQUE – 140NM HORSEPOWER – 54HP CHARGE – 3.8 HOURS 0-100 km/h – 4.5s RANGE – 150KM + *mixed |

*Mixed is common of metropolis and freeway driving together with re-gen of the brakes in cease/begin metropolis

*Trip away pricing contains all on roads and seller prices and excludes any extra choices and transport prices.

Each the Alpha and Delta are present process extra testing together with real-world vary, energy and suspension testing, so we’re hopeful we’ll be capable of exceed our buyer’s expectations, however for the second we’re being conservative with our estimates.

We now have 4 colors for buyer to select from. Atomic Silver, Darkish Matter Black, Radiate Aluminium (brushed aluminium tank cowl and rear cowl) and a model new Carbon Fibre choice with gloss carbon on the tank cowl, rear cowl and stomach pan and a matte carbon on the entrance and rear fenders and belt cowl.

We even have two seat trims in both darkish tan or black artificial leather-based that’s extremely sturdy. We’re persevering with to discover leather-based options for each our bikes, equipment and attire together with mushroom and cacti leather-based.

You may take a look at the bikes and mess around with our customized bike builder on our web site.

The place are the Savic bikes being made?

All of our bikes have been designed and engineered in West Melbourne, with parts sourced globally from India, China, Europe and Australia. We then hand assemble every bike from the bottom up in our meeting facility in West Melbourne. We will probably be handing the primary of the C-series bikes over to prospects by our Melbourne Savic Bikes showroom (which will probably be opening later this yr) or direct to interstate buyer’s doorways with our transport companions.

We now have future plans to develop our gross sales community with boutique Savic Bikes dealerships throughout the nation in addition to a partnered service assist community, though most of our prognosis and updates will be capable of be performed over the air as our bike is 4G linked. Our software program crew has totally developed our linked rider experiences on-site and will probably be persevering with to develop and repair our prospects remotely from our Melbourne premises.

What manufacturing methods are used to provide a Savic bike?

Right here’s a breakdown of how among the different parts of every C-series bike is made:

Gravity Die Solid Aluminium – Frames / Enclosure

Low-Strain Die Solid Aluminium – Rims

Freezing rear hub previous to rear axle bearing urgent – tolerances are tremendous tight!

Laser welding – battery cell terminals to bus bars

PCB Printing & Choosing – Totally Automated Electronics board manufacturing

Injection Moulding – Some plastic parts

Vacuum Forming – Seat Substrates

3D Printing – At the moment exploring native 3D printing of some parts

What are among the technological highlights of the C-Sequence other than the battery and drive practice?

Belt pushed – clear, excessive sturdiness, quiet, low upkeep

Additionally, the C-series bike’s entrance pulley is concentric with the swingarm pivot eliminating the necessity for a tensioner pulley on the belt. The instrument cluster & software program and linked to a rider expertise with over-the-air diagnostics and updates. Entrance suspension is totally developed in-house and we will probably be utilizing proprietary entrance and rear suspension tailor-made to the C-Sequence.

What challenges did you face with homologation and registration?

It did take a monumental effort for the engineering crew to get by the ABS improvement with Bosch Australia. It’s an intense course of however a essential one and we had a fantastic final result. That was a large milestone we had been in a position to have a good time in September 2022.

Since then, we sailed by all the exams fairly easily for our ADR (Australian Design Guidelines) utility and now we’re simply taking part in the ready sport as we look forward to the federal government to test over the paperwork and provides us the ultimate tick of approval for street registration. Sadly, it’s a prolonged course of that’s in dire want of an overhaul and we’ve included this in our submission together with numerous different electrical automobile producers in Australia in response to the latest nationwide Electrical Car Technique session paper.

When will Savic be fulfilling its first buyer orders?

Our first buyer deliveries are pending ADR approval however we’re hopeful we’ll be capable of get just a few out by the tip of this yr. In both case, we intend on ordering our first batch of serial manufacturing components in January 2023 for a March supply timeline for the primary 25 prospects. Our prospects are throughout our timeline and have been very affected person with us as we’ve constructed as much as this thrilling second in Australian historical past.

We’ve simply hit 235 orders in complete throughout two manufacturing runs, and we’re nearly offered out of our second run with solely 15 construct slots remaining. We plan to start out the second manufacturing run in late Q2 2023 which is de facto thrilling and humbling for the crew. We preserve our prospects up to date each time any dates or milestones change and wish to share our wins with them. We’ve clearly constructed one thing that individuals are excited to personal and journey and we are able to’t wait to get them onto the street.

To remain updated with Savic’s progress, or reserve one of many few remaining C-series electrical cafe racers of their second manufacturing, head over to the Savic web site.

SAVIC MOTORCYCLES