- The danger of contamination of soil and water from EV batteries is big, if improperly disposed on the finish of their lifespan.

- Batteries not solely comprise uncommon earth supplies, but in addition have “eternally chemical substances” of their cathode and the electrolyte.

- Researchers on the UChicago Pritzker College of Molecular Engineering are designing a battery that does not use these dangerous chemical substances within the first place.

The worldwide demand for lithium-ion batteries is forecast to extend from 700 gigawatt-hours in 2022 to a whopping 4.7 terawatt-hours by 2030, in keeping with Mckinsey & Firm. That’s as a result of battery utilization is not only rising in electrical autos, but in addition in electrical home equipment, drones, grid-level power storage and dozens of different functions. However their soiled secret of utilizing dangerous chemical substances hasn’t been addressed but.

Along with uncommon earth supplies in EV batteries and traction motors, these elements additionally use harmful chemical substances referred to as PFAS, which stands for per- and polyfluoroalkyl substances. They’re in all the things, proper from our garments to the non-stick kitchen pans, in keeping with the Nationwide Assets Protection Council. They don’t break down within the atmosphere and might even infiltrate human our bodies by meals and water, therefore the title “eternally chemical substances.”

Now researchers on the College of Chicago are designing next-generation EV batteries that don’t depend on PFAS. Each a cathode and the electrolyte in a typical lithium-ion battery have PFAS. They assist in preserving the interior battery construction collectively. UChicago researchers stated having PFAS within the cathode and the electrolyte just isn’t a elementary requirement. They declare to have a workaround that doesn’t have an effect on efficiency.

“We’re demanding extra from our batteries. We wish low-temperature efficiency. We wish high-temperature efficiency. We wish quick charging. We wish lithium metallic batteries. These are issues that we’re demanding as customers,” Chibueze Amanchukwu, a professor on the UChicago Pritzker College of Molecular Engineering stated in a weblog submit.

“What the scientific literature is doing now’s to say, ‘Oh, let’s add extra fluorinated elements into the electrolyte.’ Virtually all of these will probably be thought-about PFAS,” he stated.

To deal with this subject, they developed a particular “non-fluorinated solvent” freed from PFAS for the electrolyte. That alone doesn’t resolve the issue. The problem is to show that the fabric will at the very least match, or enhance the efficiency of a typical EV battery.

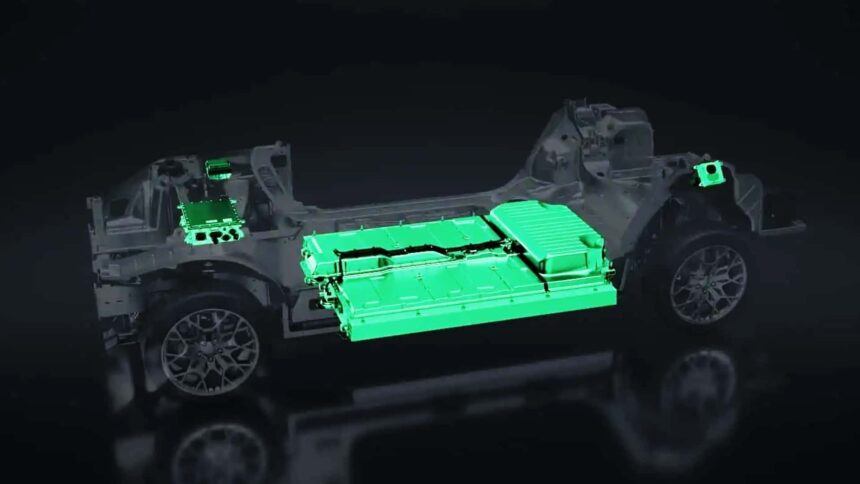

Picture by: Mercedes-Benz

Seems the cells freed from PFAS demonstrated higher ion-pairing, which means they had been extra power dense. They’d extra resistance to excessive temperatures, with the biking apparently secure from 60 levels Fahrenheit to -40 levels. In addition they had higher capability retention, which means the battery won’t solely last more, but in addition proceed to carry out at a excessive stage in the long run.

In fact, these batteries are within the lab experiment part and nowhere close to coming into manufacturing. However the level of the research is to showcase that environmental considerations for EV batteries might be addressed proper on the design stage.

When tens of millions of end-of-life EV batteries enter the recycling and second-life phases by the top of the last decade, the chance of them contaminating the atmosphere is big, particularly if they are not correctly dealt with. PFAS has been linked to extreme well being hazards, together with developmental results in kids and reproductive results in ladies, in keeping with the Environmental Safety Company.

Proper now, the worldwide EV motion has adopted the move-fast-and-break-things method prevalent amongst Silicon Valley tech giants. Being first to market is extra necessary than resolving the potential injury EV batteries might trigger years or many years later. Hopefully, with stricter rules and options like these, future battery developments can take a extra cautious and eco-friendly method.

Have a tip? Contact the writer: suvrat.kothari@insideevs.com